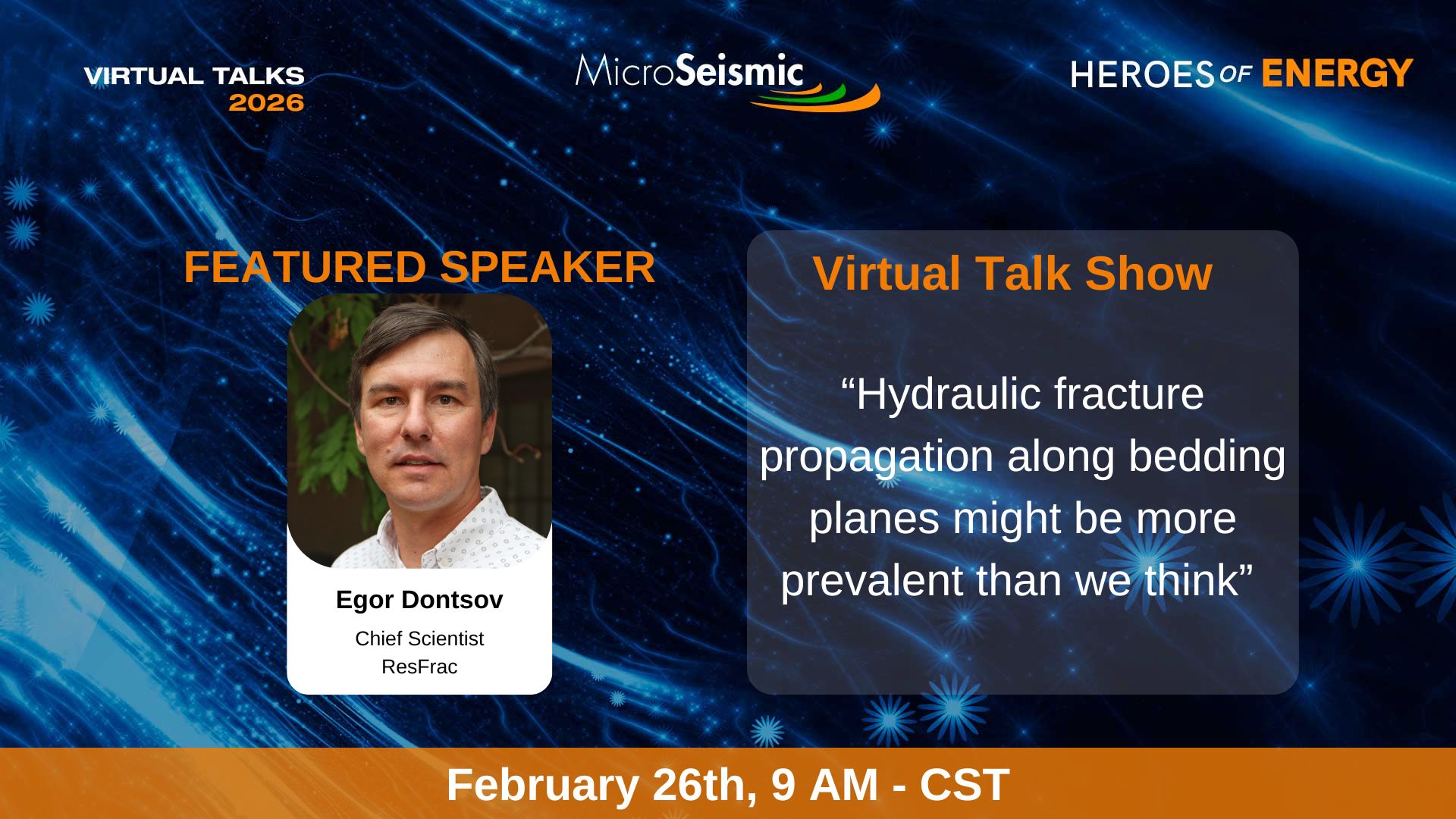

Hydraulic fracture propagation along bedding planes might be more prevalent than we think

Advancements in seismic acquisition technology are delivering higher-resolution data while minimizing environmental footprint.

The Houston geothermal community came together to celebrate World Geothermal Energy Day on October 17th, 2024. Hosted by MicroSeismic at the iconic Karbach Brewery, the event showcased the growing momentum of Houston’s geothermal

Read MoreGeothermal development began with hydrothermal systems and has grown to incorporate enhanced geothermal systems (EGS) and closed-loop systems deemed the next generation of geothermal development which will vastly expand the

Read MoreTo achieve effective CO2 storage, it is imperative to monitor, report and validate (MRV) the process continually via the CO2 protocols to ensure containment of the stored carbon. Dr. Peter Duncan,

Read MoreA growing number of bipartisan bills are being proposed for expanding geothermal energy. Geothermal Rising (GR) is the main professional and educational organization for the geothermal community in the United States

Read MoreTwo new workshops for the geothermal industry took place this November, the Society of Petroleum Engineers and Geothermal Rising hosted a workshop on Mutual Challenges and Solutions in Oil &

Read MoreI never imagined we would delve into the world of capturing CO2. These days, it’s a topic we hear about constantly. Day after day, countries like the United States offer

Read More